If you want to improve any and all areas of your business, you have to make some changes. Just the word “change” can strike fear into the hearts of everyone in your group (and probably you too). Don’t worry, the changes are going to be worth it. To make those changes stick, you are going to need a process.

I know, processes suck. But they also work. The discipline to map out, execute, measure and adjust the processes are what make the difference in success or failure. How do we go about doing this?

- What area could be improved with a good process? What goal are you trying to accomplish? They can be big or small in nature and everything can be mapped out. For example, you can have processes to onboard new employees, check-in and prep new cars from the factory, sell a car, recondition a used car, park cars in the inventory, remove snow from the cars/lot in the winter (for those of us up north), answer the phones, clean the building or evaluate employee performance. The list is as long as you want it to be.

- Don’t try to do everything at once. Just pick what you feel is the most pressing issue and go from there.

- Think from the end. Now that you’ve picked a particular area, what is the objective? Let’s say we’re trying to improve used car reconditioning. The end goal is a fully reconditioned car, properly merchandised and for sale on your lot/website in a timely manner (however long you want it to be, and the shorter the better).

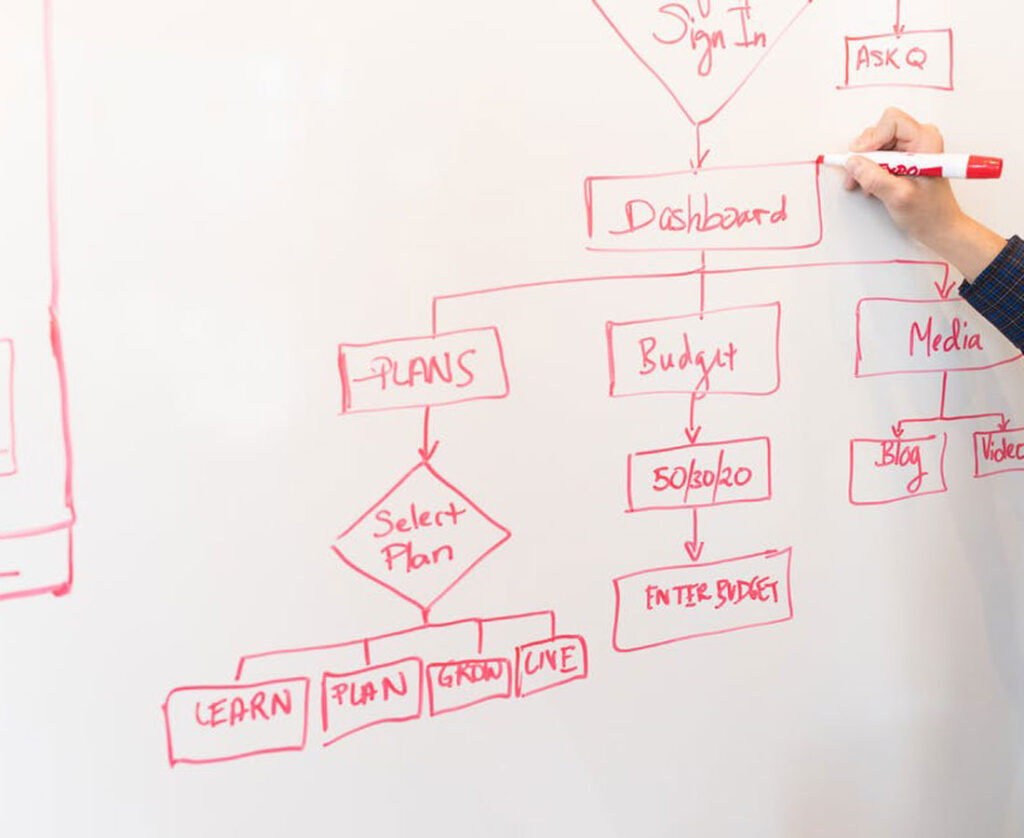

- Map it out. What are all the little steps in the reconditioning process along the way? Don’t leave anything out. Put it all down on paper or in the electronic document. If you’re collaborating (and I highly recommend you do), use a whiteboard or something similar so you can get everyone’s input. Reconditioning a used car has all sorts of little elements that can hinder your goal of a timely turnaround for getting it on the lot.

- Clean it up. Once you have every step, write it down and make sure all stakeholders are accounted for and accountable to what you want for that process. Keep making changes but also don’t think you have to get it perfect before launching. Remember that you’re not writing the Ten Commandments, you’re just trying to improve an area of the business!

- Get everyone on the same page. If everyone involved doesn’t know the end goal in mind, they can unwittingly throw you off course. If they understand the impact of their actions or inactions (“Oh, I’ll get around to detailing that car when I get time”), they can better align their performance with the goal. A lot of times your people may not see the “why” in the process – it’s your job to make sure they know!

- Execute. Get out there and try it out. Get dirty and observe what’s going on in each step. What areas need attention? What unexpected obstacles did you encounter? What needs to be changed? I guarantee some element will need tweaking. Based on the measurement metrics you chose in the mapping step, does the data tell any stories?

Remember that data does not make the decisions for you, it just provides the underlying evidence for you to make a choice. Back to the used car reconditioning, watch a car, go through the process and make notes on what is preventing it from going through the system quickly and efficiently. Talk to the stakeholders (again) and find out what efficiencies are there. - Adjust and continue. There is really no end to the process, just a lot of continuing execution. Make any changes as circumstances arise (our business does change rapidly) and go from there. For example, you’re not going to stop reconditioning used cars, so use the process every day. A solid process will never truly run itself because it needs to be inspected and monitored, but if something is off-kilter you can just refer everyone back to the process and see if things are on track or not.

Like I said, you can have processes for almost anything in the store. If you tackle them one by one and measure them accordingly you’ll have a dealership that runs much more smoothly than if you just come in and wing it!

What say you? Do you have any tips for writing, planning and executing your processes? What lessons did you learn along the way? I’d love to hear your feedback.

Make it a great day!

Dan